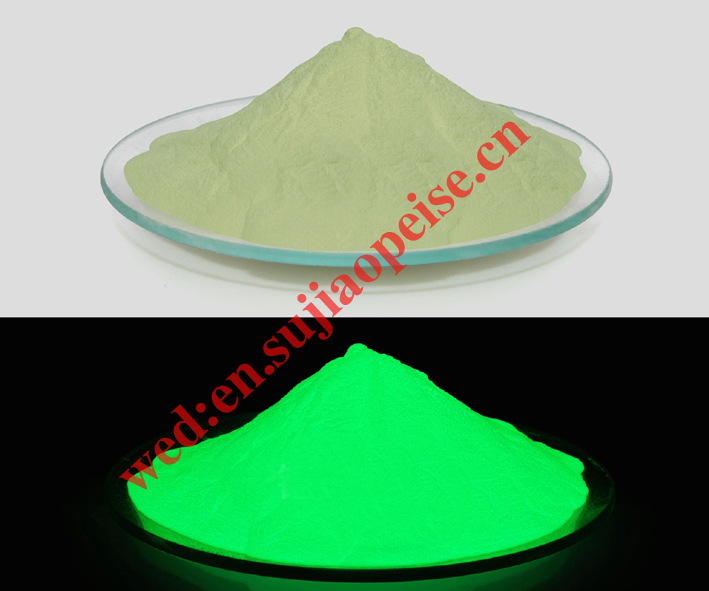

Plastic luminous powder

Source:HuizhouYingguang Plastic Pigments Co., Ltd Released in:2025-04-10 Hits:

Long - lasting long afterglow luminous powder injection luminous plastic products technical support the use of methods

◆ luminous powder use instructions luminous powder can be applied to different plastic processing technology, such as injection molding, extrusion, pouring, calendering, mixing, etc., if the first preparation of luminous plastic masterbatch, and then prepared by the masterbatch products, luminous effect will be better The

◆ luminous powder preparation:

1, the use of better finish equipment, to minimize friction, reduce damage to equipment, but also reduce the pollution of the powder.

2, because the coarse particles can be prepared by screw machine masterbatch, it is best not to filter screen.

3, injection molding products can be a molding, just the powder evenly stick to the pellets can be, usually by adding white oil or polyethylene wax.

4, luminous plastic products if the use of masterbatch preparation will be better, can use masterbatch plate, film, tube, silk and other luminous products.

5, long-lasting luminous powder is the most bogey and iron friction, such as high-speed friction will lead to black.

6, luminous pigments and plastic (silicone, rubber) ratio of the general plus 4-10% on the line

◆ luminous powder use and precautions:

1, the equipment is too rough or too complex process is not conducive to the production of light-emitting products.

2, the mixing process can not be used metal high-speed mixing, can be used non-metallic lined container stirring.

3, the preparation of masterbatch resin used when the choice of pp, ps, as, pc such transparent resin or better transparency pe, sometimes with opaque abs products.

4, will prepare the masterbatch, the material mix, add to the extruder, the normal processing temperature of 20 degrees lower processing,

The Ingredients: first proportion of good luminous powder (content of about 2 ~ 10%), adding a small amount of diffusion oil (paraffin oil, white oil) stirring into a paste, then add raw materials, stirring, plus toner stirring, Stirring evenly, the time should not be too long to avoid the precipitation of luminous powder, pay attention to the most boiled powder with iron and other heavy metal friction, will make raw materials black. Can use the materials are: PP, PE, PVC, PU, PS, ABS, TPR, EVA, PMMA, nylon and so on. The more transparent the plastic material, the better the luminous effect, the toner as much as possible with fluorescent toner, add the less the better.

5. Injection: injection molding machine temperature to a minimum, can be injection can be expected in the injection molding machine time should not be too long, so as not to burn.

6. Injection molding machine: different machines injection molded products, there are differences, new machines and old machines, domestic machines and imported machines, which need to slowly debug to solve.

7. Luminous powder: long-lasting luminous powder in the injection of various reasons, injection molding technology, injection molding machines, may cause black, according to their own circumstances to determine the experiment.

【Previous】:yellow green light

【Next】:Silicone luminous powder (Gree...