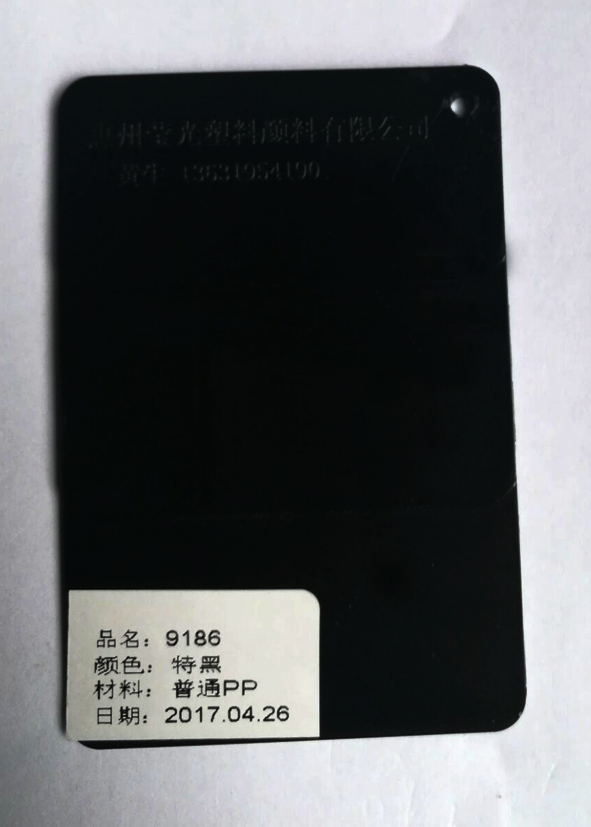

mode:9186

Source:HuizhouYingguang Plastic Pigments Co., Ltd Released in:2025-04-10 Hits:

Black masterbatch is divided into ordinary black masterbatch, special black masterbatch, common black masterbatch, high-gloss black masterbatch, no carrier black masterbatch, for high pigment masterbatch, engineering plastics, styrene plastic coloring, High brightness, high dispersion, injection, pumping tablets, compatible with PS, HIPS, AS, ABS, PC, PA, POM, PMMA and other senior engineering plastics.

Black Masterbatch Category:

1. Advanced injection of black mother for cosmetics box, toys, electrical appliances and other high-level products.

2. Ordinary injection of black mother for general household plastic products, industrial containers.

3. Advanced blown film masterbatch for ultra-thin products blow molding coloring.

4. Common blown film black mother for general packaging bags, woven bags of blow molding coloring.

5. Spinning black mother for textile fiber spinning coloring, black mother pigment particles fine, high concentration, strong coloring, heat, light resistance is good.

6. Low color masterbatch for the manufacture of color quality requirements of low-level products, such as trash, low-level containers.

Black Masterbatch Advantages:

Environmental protection, non-toxic, tasteless, smoke-free, SGS, ROHS certification testing, product surface smooth glossy, strong coloring, color spots and color will not appear.

Usage: stir with the raw materials can be produced

Dosage: Suggested dosage 0.5% -2%

Temperature: ≥ 300 ℃

Melting point: 110-300 ℃

Moisture: ≤0.05%

Packaging optional: Color Masterbatch bag, no paper bag, black Zifeng Dai, black sealed bags, white printing bags.

Stacked weight: 1000KG / m³

Storage: Store in a cool dry place, avoid exposure, rain.

Note: The above data is not used as a specific technical specifications, the basic experimental data, only as a reference for this product performance.

【Previous】:model:2020B

【Next】:Light diffusion masterbatch